Feel Good Fuel: Making Biofuel in Maine

By Tony Zeli, Publisher & Editor

Personally, I found it hard to believe that this “feel good fuel,” as Maine Standard Biofuels’ founder and president Jarmin Kaltsas calls it, could really run my oil furnace – and without conversion.

As incredulous as ever, I took the tour that Jarmin graciously offered and saw for myself how Maine Standard turns used veggie oil into a fuel any home furnace would love to guzzle.

USM students painted some of the storage tanks at Maine Standard Biofuels’ Portland plant, including this one with a Portland skyline. -Photos by Tony Zeli

RECYLCE YOUR VEGGIE OIL

At its facility on the outskirts of Portland, Maine Standard Biofuel collects dirty cooking oil, filters and processes it, and cuts it with conventional heating oil. It is a type of biodiesel, but not to be confused with ethanol. Unlike a product like E85 (used as an auto fuel), Maine Standard’s B20 biofuel is not made from energy crops.

Maine Standard recycles cooking oil from about 1500 businesses throughout the region, from Presque Isle to New York State. Consider the average restaurant produces roughly 100 gallons of used cooking oil per month. That’s 1200 or so gallons of oil per year from 1500 locations… that’s over one million gallons. Currently, Maine Standard Biofuel only transforms about half of it into biofuel. They send the rest to other biofuel producers.

But this first step in the process is not reserved for restaurants and food processors. Individuals can recycle their used cooking oil through the local composting company Garbage to Garden or arrange to drop off directly with Maine Standard Biofuels.

NO FRIES WITH THAT

Used cooking oil is filtered and then sent through this centrifuge at 9000 rpm to separate out any water.

Of course, in this case, you don’t want fries with that. The next step is filtering and processing the used cooking oil so it can be combined with ultra-low sulfur home heating oil. The mix ends up at 20 percent recycled oil and 80 percent regular heating oil.

Next, they filter the oil and send it through a centrifuge at 9000 rpm to separate out any water.

The filtered oil is now ready for pretreatment. Maine Standard mixes the filtered oil with glycerin, a byproduct from biodiesel production, and this prepares it for mixing with chemical diesel.

After pretreatment, the oil is ready for processing. The oil mixes with chemicals in a process called transesterification and out comes biofuel and a waste product of glycerin.

MAKE SOAP

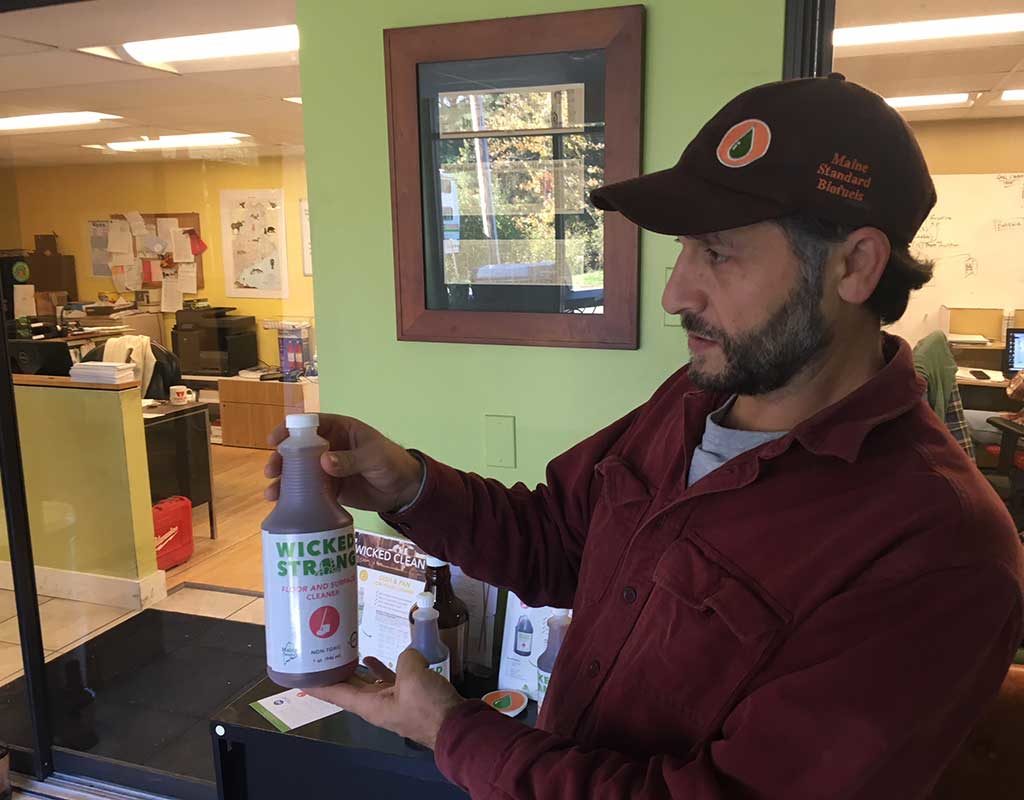

“The oil we pick up from the restaurants, we end up bringing it back to them in the form of soaps,” says Maine Standard’s Jarmin Kaltsas.

To close the loop, Maine Standard turns their waste glycerin into a line of cleaning products. They are expanding their product line regularly and now even have a bio-based Tiki torch oil.

The bio-cleaning products are becoming popular among the restaurants that use their oil recycling service. And readers can find the products at Maine Hardware on St. John Street.

Founder Jarmin Kaltsas with a bottle of Wicked Strong cleaner made from the glycerin waste product created by biodiesel production.

HEAT HOMES & FUEL CARS

For years Maine Standard Biofuel has produced a B99.9 (basically 100% biodiesel) product for use in diesel motors. But they’ve only been processing the B20 product we use in our home furnaces for the last couple of years.

The oil can be mixed with conventional oil. In fact, Maine Standard Biofuels offers auto-fill or one-time delivery at competitive prices. They also provide servicing.

The oil runs in any furnace, even newer 90% efficient burners. In fact, it runs cleaner and with less soot.

And if you have the right type of diesel vehicle, you can stop by the pump at their location on Ingersoll Drive and fill up!

Maine Standard Biofuels is open to classroom and group tours. For more information visit https://www.mainestandardbiofuels.com.